Polypropylene (PP) textiles are everywhere — from construction sites and farms to hospitals and homes. But what are they exactly? And how is Renegade Plastics pushing the boundaries of what’s possible with this plastic?

Let’s explore what makes PP textiles so useful, where they’ve been revolutionary, where they fall short, and why Renegade’s coated PP fabric is such a breakthrough.

What is a Polypropylene Fabric?

Polypropylene is a thermoplastic polymer made from propylene monomers — a lightweight, durable plastic that can be spun into fibers or extruded into sheets. Globally, polypropylene is the plastic produced in the largest quantities, surpassing polyethylene (PE) and polyvinyl chloride (PVC).

PP textiles are a subset of the versatile applications of this polymer. Traditionally, PP textiles have come in two main forms:

- Woven polypropylene — Interlaced PP threads providing strength and dimensional stability.

- Nonwoven polypropylene — A web of bonded fibers or films, providing softness, flexibility, and filtration properties.

Since its rise in the 1960s, woven polypropylene has transformed industries thanks to its affordability, chemical resistance, and food safe applications. Some of its most revolutionary applications include:

- Agriculture — Bulk bags for grains, seeds, and fertilizers revolutionized logistics and reduced material waste.

- Construction — Ground stabilization fabrics enabled more cost-effective infrastructure projects.

- Packaging — Woven PP sacks replaced traditional jute and paper bags for rice, flour, and animal feed, improving food safety.

- Disaster Relief and Aid — Lightweight woven PP tarps and sandbags became essential tools in emergency response around the world.

These innovations made woven PP a backbone of modern society — but they also revealed its limitations, especially as performance demands and sustainability expectations have grown.

Limitations of Traditional Polypropylene Textiles in Industrial Applications

While traditional woven PP textiles have been revolutionary, they come with certain limitations in industrial contexts:

- Durability – The woven fibers break down easily with abrasion and repeat usage leading to a short lifetime of use.

- UV Vulnerability — Without UV stabilization, woven PP degrades under prolonged sun exposure, becoming brittle and prone to failure. Think of how those blue plastic tarps, which are often polyethylene, left out in the yard all summer become brittle and shed little pieces of blue plastic everywhere.

- Moisture Permeability — Woven structures allow air and moisture passage, which is great for some applications, but additional coatings or liners are needed for waterproofing.

- Difficult to Recycle — The woven structure of PP bags can make it hard to shred and granulate them into smaller pieces suitable for recycling. Additionally, to meet industrial needs, woven PP is often laminated or coated with other types of plastic, turning it into a composite that’s hard or impossible to recycle.

Because of all these limitations, woven PP textiles have been confined to single use applications and narrow commercial markets. But given the successes of rigid polypropylene due to its excellent durability and chemical resistance, we knew there had to be a pathway to a better PP textile.

The Renegade Innovation: A Monomaterial Breakthrough

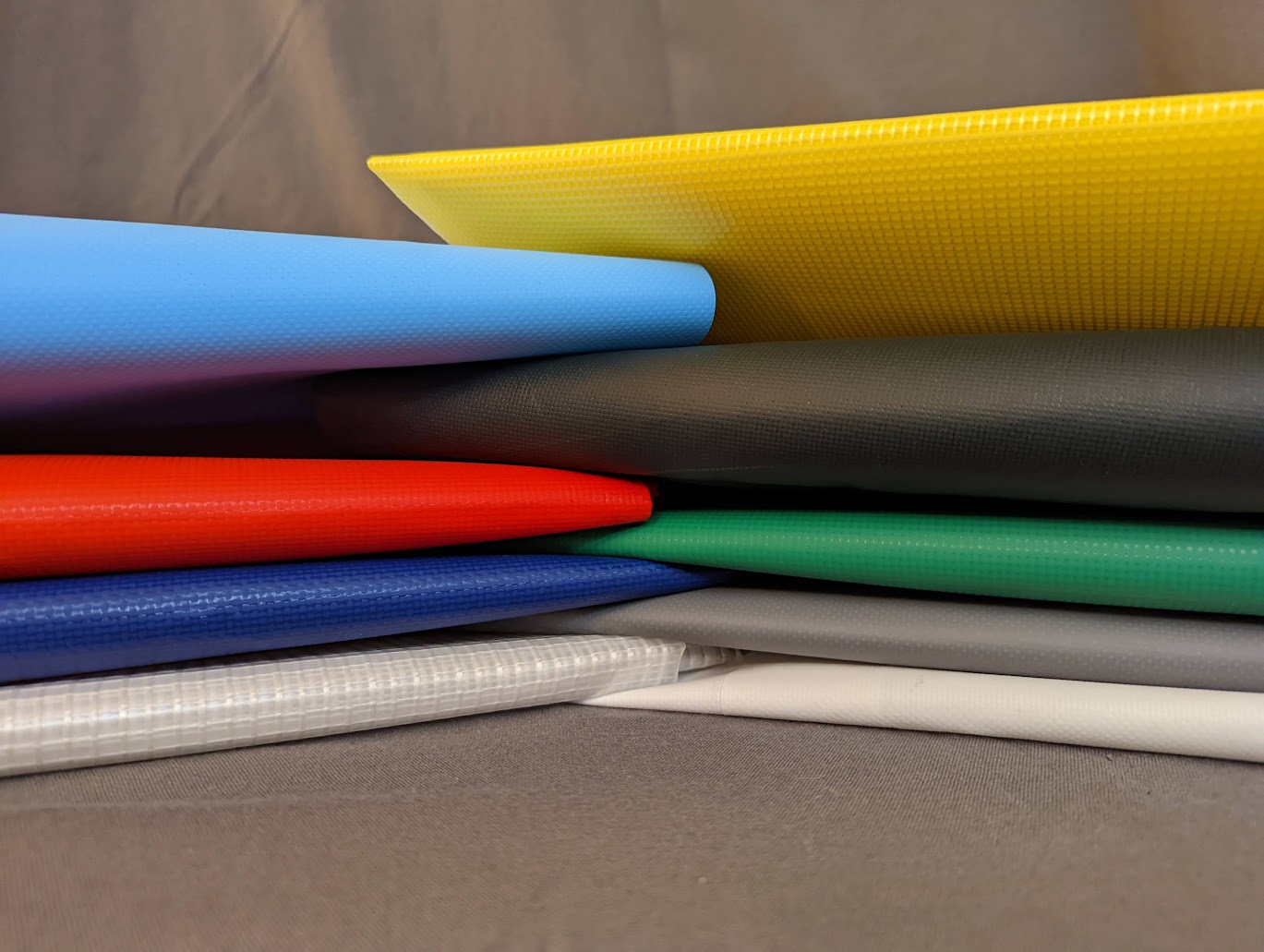

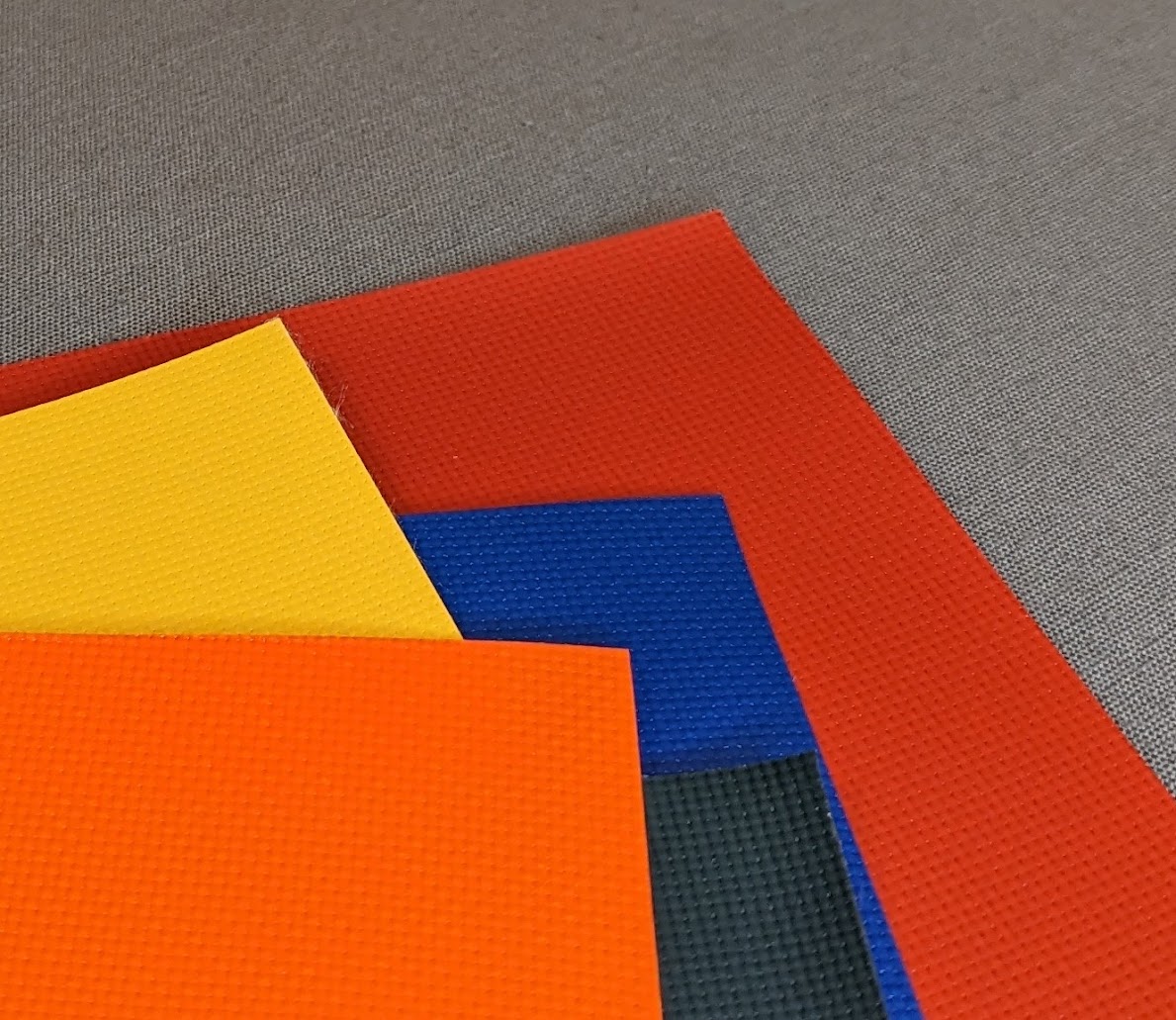

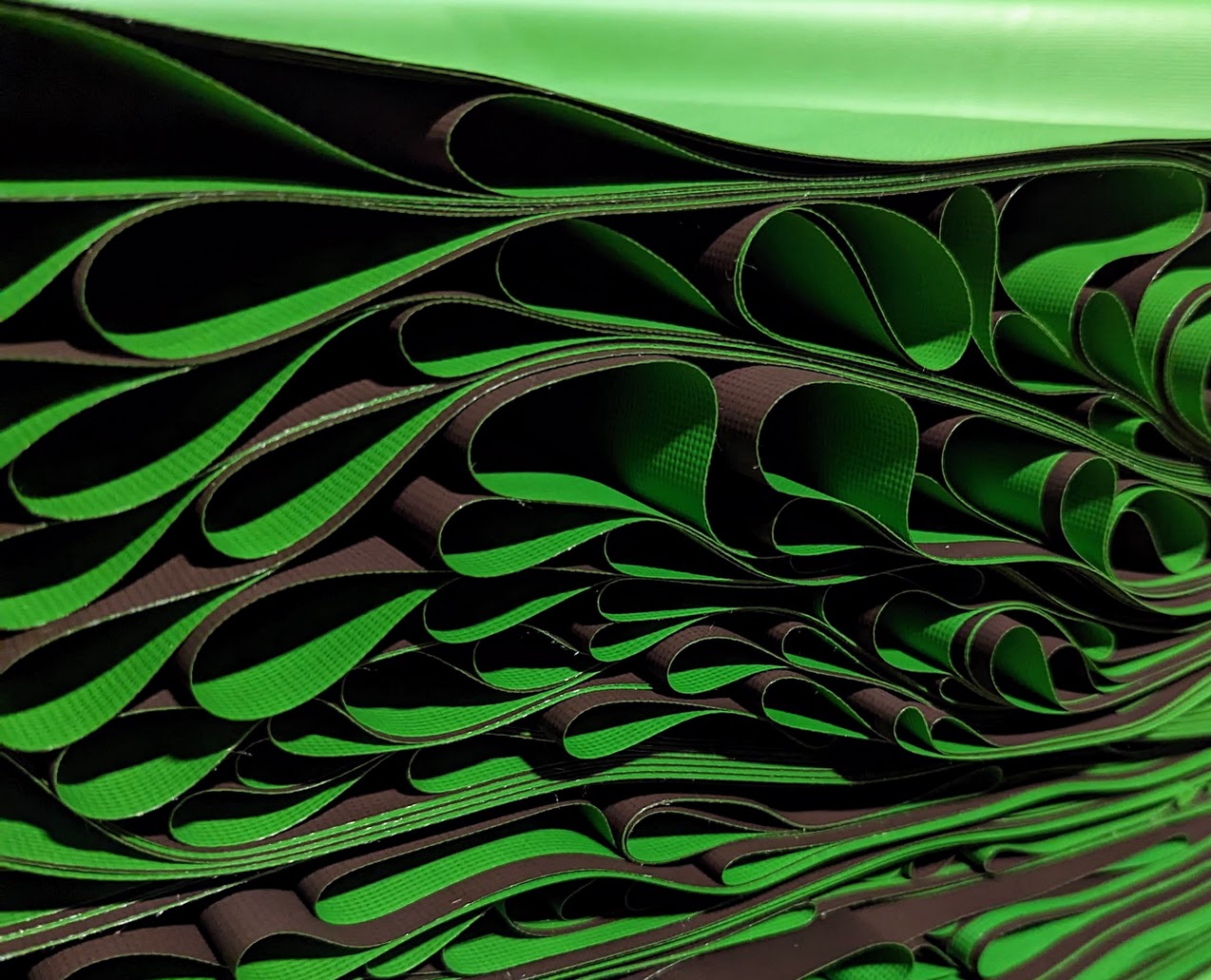

Renegade’s fabric sandwiches a layer of woven PP fibers between two layers of Renegade’s proprietary polypropylene based coating. This design:

- Provides the strength and stability of a polyester or nylon woven fabric,

- Adds the smooth, protective surface of a durable polymer coating,

- But does not include any non-PP plastics like PVC, polyurethane (PU), or silicone or other potentially toxic additives like phthalates and PFAS.

The result? A mono-material fabric that’s durable, waterproof, UV-resistant, weldable, and designed for closed-loop systems.

Advantages of Renegade’s Approach to Coated Fabrics

Most coated woven fabrics rely on an internal scrim made from polyester or nylon, or PE, covered by external layers of PE, PVC, PU, or even silicone for waterproofing and durability — making them difficult or impossible to recycle — Renegade Plastics offers something entirely new.

✅ Lightweight but strong — Excellent strength-to-weight ratio.

✅ Moisture and chemical resistant — Repels water, resists mildew and many chemicals.

✅ Durable and abrasion-resistant — Withstands rough use in demanding environments.

✅ UV-resistant — Extends outdoor longevity and reduces material degradation.

✅ No PVC, phthalates, or PFAS — Safer for people and the planet.

✅ Designed for circularity — The monomaterial design improves performance while enabling recycling.

Compared to traditional woven PP fabrics, Renegade’s materials provide the performance of Frankenstein multi-polymer materials while maintaining all the benefits of polypropylene.

Imagine the Possibilities

Renegade Plastics’ coated PP fabric opens the door to exciting new possibilities, including:

- Industrial covers — Machinery covers, truck tarps, and pallet wraps that are strong, weldable, and built to live outdoors.

- Marine and outdoor coverings — Boat covers, outdoor furniture covers, and grill covers that retain flexibility after sun, rain, and snow exposure.

- Agricultural covers and liners — Durable, UV-resistant, and non-toxic alternatives to traditional covers or pond liners.

- Bags and outdoor equipment – Lighterweight than PVC or PU coated textiles, offering durable yet stylish water repellency that is non-toxic and cost-effective.

- Event and promotional materials — Printable, weather-resistant banners and tents that support circular material streams.

These are just some of the areas where Renegade’s innovation could displace legacy materials — offering both high performance and sustainability.

Let’s Work Together – Your Ideas, Our Fabrics

Woven polypropylene has long delivered versatility and affordability for consumer applications. But thanks to Renegade Plastics, we now have a version of PP textile that is also durable and strong while opening the door to a more sustainable and non-toxic materials future.

Whether you’re a brand, manufacturer, or conscious consumer, understanding innovations like this is key to making better choices for people and the planet. So if you have an idea for how our PP-coated fabrics might improve your company’s product offerings and competitive advantage, let’s work together. Our sales and product teams are ready to assist you with technical questions and fabrication knowledge.

5 Polypropylene Fabric Questions We Get Asked

1. How is the flexibility of your coated PP fabric?

We have two main product lines with varying amounts of flexibility based on the coating thickness. For example, our Flex-370 line had only slight damage to the coating after 50,000 cycles for a Bally Flex test (ASTM D6182). Our PPI line is slightly stiffer than the Flex line, but still pliable.

2. Will Renegade’s coated PP fabrics crack at low temperatures?

Renegade’s products are unique in the flexible polypropylene world because they are cold resistant. All of our product lines pass ASTM D751 (4 hours at -40 degrees F/-40 degrees C) with no cracking. Some of our product lines can even withstand -60 degree F/-58 degree C temperatures for 4 hours without cracking.

3. How do I clean PP fabrics?

Polypropylene fabrics are best cleaned with soap and water to remove any grim and dirt. However, polypropylene fabrics, including Renegade’s products, can also be cleaned with a bleach solution for tough applications. In fact, polypropylene is inherently chemically resistant to a wide range of chemicals, including many acids, bases, and solvents

4. Isn’t polypropylene used to make yogurt containers?

Yes! The polypropylene polymer is extremely versatile. Yogurt containers are formed through thermoforming, where plastic sheets are heated and molded into shape, or injection molding. Polypropylene is known for being food safe. Rigid polypropylene, such as yogurt containers, are also widely accepted in municipal recycling programs.

5. Can I print on Renegade’s PP fabrics?

Yes! We use corona treatment to prepare our fabrics for printing. This step is necessary because of polypropylene’s chemical resistance, which also makes it resistant to many inks. We do encourage users to only use latex inks as these can be removed with non-toxic methods and do not reduce the recyclability of the fabric.

Interested in Our Fabrics?

Contact Us