Bonding & Adhesives

Stick to the Plan: Glues & Tapes That Actually Work with Renegade Fabrics

Glues & Tapes That Actually Work

When you’re working with high-performance coated fabrics, there’s nothing worse than a bond that bails on you. One minute everything’s holding tight and the next, your sign is flapping like a beach towel in a hurricane. Since Renegade fabric has distinct differences compared to vinyl or canvas fabrics, you may need to rethink your adhesion approach.

Don’t worry, we’re here to help. This article will go over:

- Glues and tapes that actually work with Renegade’s polypropylene-based, plasticizer-free coated fabrics,

- Adhesives to avoid, and

- Tricks to give your bonds staying power.

Why Bonding to Renegade Fabrics is Tricky (on Purpose)

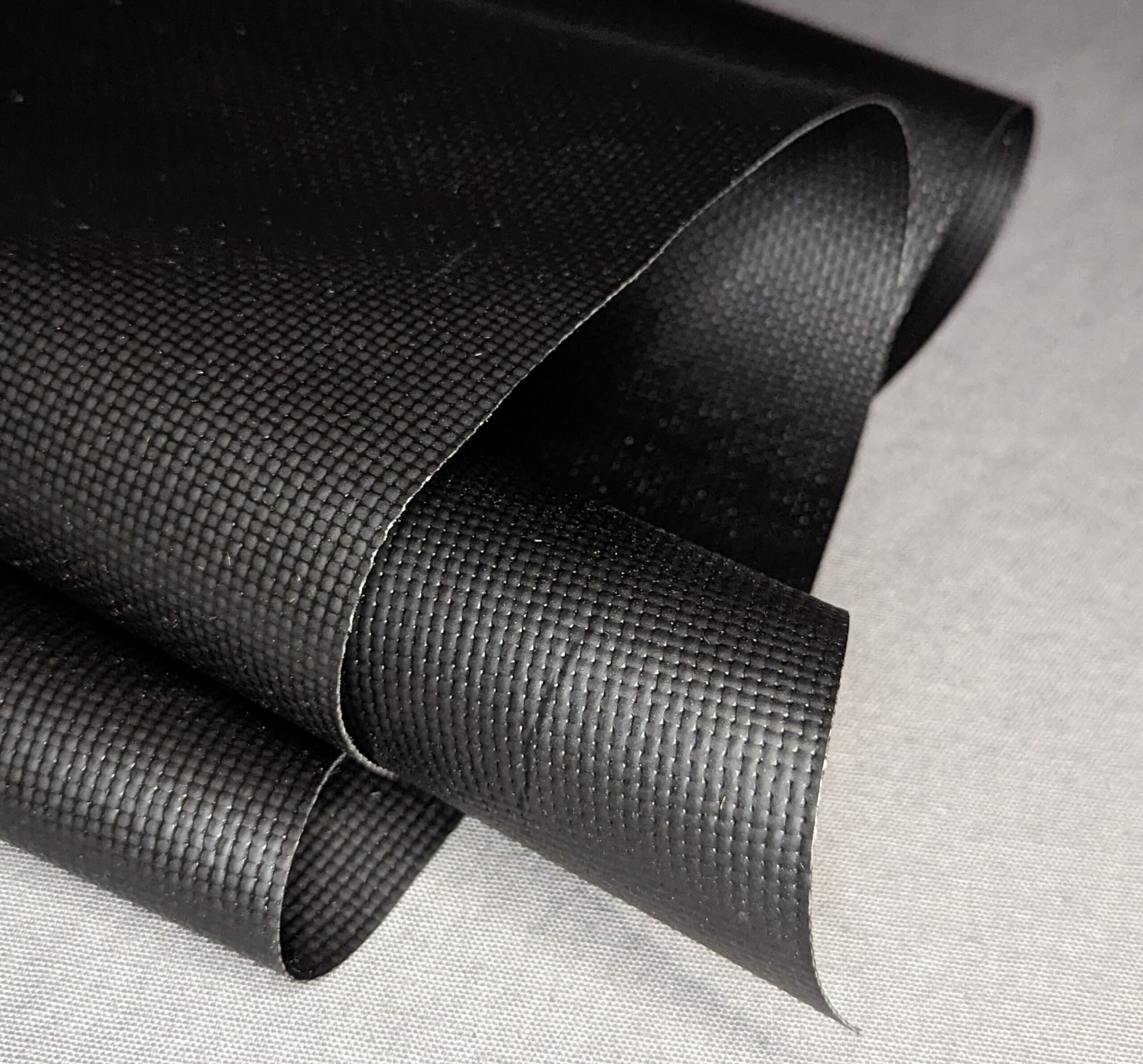

Renegade fabrics are built differently. They’re not vinyl (PVC). They’re not canvas. And they’re not trying to be. These fabrics are coated, polypropylene-based, free of phthalates, free of intentionally added PFAS, free of plasticizers, and lead-free. That’s great for sustainability, durability, and safety—but it makes adhesive selection a little more… shall we say, selective.

The challenge? Surface energy. Polypropylene is a low surface energy plastic. That means most adhesives (even the ones that work beautifully on vinyl) will shrug and peel right off.

Best Option

Gorilla Waterproof Patch & Seal black 4” wide by 10’ Low Density Polyethylene (LDPE) – This tape is heavy-duty industrial tape for patching holes, cracks, gaps, and tears on material used outdoors. It is waterproof, flexible, and air tight. We recommend this for use with Renegade fabrics when industrial strength is needed. Because it’s LDPE, it doesn’t need to be removed before recycling. A win-win situation.

Economy Option

Crawlspace DIY White Vapor Barrier 4” wide by 180’ Polyethylene (PE) – This tape was initially made for attaching sheets of PE for vapor barriers in crawlspaces, but also works great for all your Renegade Plastics’ fabrics. It has excellent moisture resistance, is thin but strong, and hand tearable. Best of all it won’t break the bank. We recommend this tape for general home and commercial patching or for bigger projects that need long strips of adhesive tape. The tape can be recycled with Renegade fabrics, so there will be no tedious cleanup at the end of your project.

Best Option for Hiding Your Mistakes

Gorilla Waterproof Clear Patch 4” wide by 8’ LDPE – This tape is perfect for blending in with the many colors of Renegade fabrics. It is waterproof, non-yellowing, and flexible. We did notice that it’s a bit less sticky compared to the Gorilla Waterproof Patch & Seal black and could be pulled off with force (tested by a member of the sales team who can also bench press more than 300 lbs, so the average person might have some difficulty). This is the tape you’ll want to use for your every day patch and attachment needs.

Best Option

Loctite 401 – Compatible with numerous metals, plastics, and even wood, this is the strongest and simplest glue we’ve found. We recommend this for attaching Renegade fabrics to other types of materials or for providing an extra layer of waterproof protection to welded seams. Loctite does not recommend this product for consumer sale or use, but if you want to use it to test the adhesion by attaching a strip of Renegade fabric to your car’s bike rack, we’re not going to stop you. For the record, it has stayed on for three years and counting…

Best Budget Option

Gorilla Contact Adhesive Clear Grip – This glue has a more rubbery feel to it when dry which might be better for waterproofing applications depending on the specific project. It is also much cheaper than the Loctite adhesive products. It does, however, take longer to dry.

Best Option for Medical Applications

Loctite 402 with Loctite SF 7701 primer – Made for ultra-performance under extreme operating temperatures up to 135°C (275°F), this glue is excellent for bonding polypropylene and is ISO-10993 biocompatible.

What Not to Use (Unless You Like Watching Things Fall Apart)

Not all adhesives are created equal. Here’s what to skip if you value your sanity:

- Vinyl adhesives: These are designed for PVC, not polypropylene. They may stick at first, but won’t hold.

- Spray adhesives: Inconsistent coverage, weak bonds, and a tendency to give up when things get humid.

Clean the surface:

Apply pressure:

Plan and prepare:

Test first:

Bonus Round: Why Welding Might Be Better

If you’re looking for a bond that holds through storms, sun, and shipping containers, let us humbly recommend: hot air or impulse welding.

Renegade fabrics are engineered for hot air or impulse welding. They bond beautifully under heat without releasing the types of toxic VOCs associated with vinyl welding. So you get strong, chemical-free seams—and workers who aren’t breathing in question marks.

Stick With Us

Not finding what you need?

When in doubt, reach out. Our team is ready to talk shop and solve whatever problem’s got you stuck.