Your Path to Success is Paved with Superior Industrial Fabrics

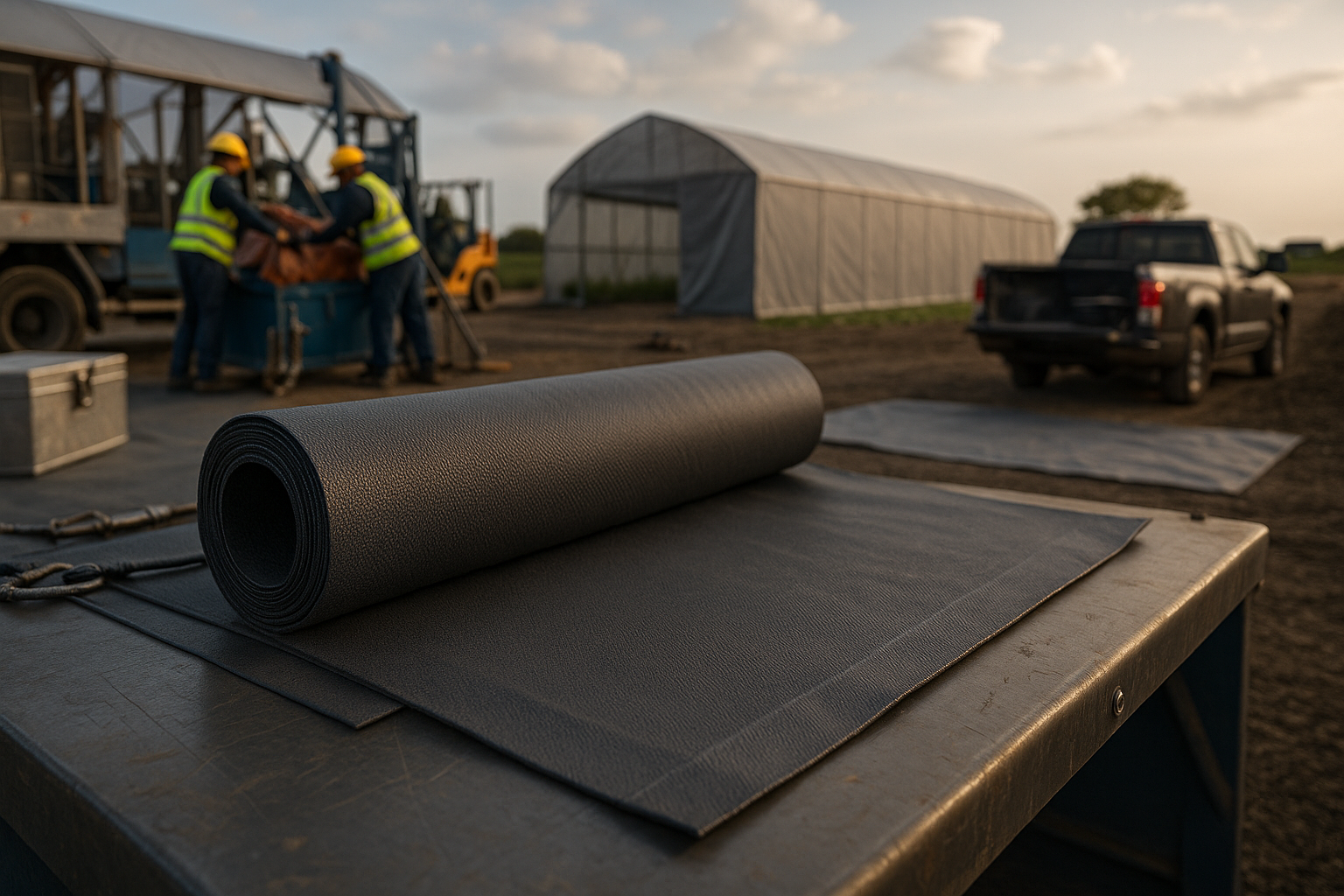

From construction and agriculture to aerospace and logistics, business operators and managers rely on materials to provide lasting, reliable protection from the elements. Renegade Plastics manufactures high-performance industrial fabrics engineered for safety, durability, and circularity.

Whether you’re reinforcing infrastructure or building a better supply chain, our coated polypropylene fabrics support critical applications with less environmental impact.

Our coated fabrics aren’t just an upgrade in material; they’re a transformation in how companies think about protection, compliance, and long-term value. Renegade serves businesses that demand reliable supply, consistent performance, and a proactive approach to sustainability.

In an industry where legacy plastics still dominate, our approach delivers a smarter path forward.

6 Instances When Industrial Fabrics Come In Clutch

Industrial fabrics are essential to countless commercial and municipal operations. Here are a few situations where Renegade’s materials make a measurable difference:

1. Machine Covers – Protect expensive equipment in manufacturing and field operations from dust, moisture, and UV.

2. Secondary Containment – Line or cover hazardous material areas in compliance with environmental regulations.

3. Dunnage and Reusable Packaging – Create lightweight, impact-resistant, and reusable packaging for intra-facility or over-the-road transport.

4. Temporary Water Storage – Build collapsible tanks and liners for rapid deployment.

5. Passenger Boarding Bridge (PBB) Canopy – Shield passengers and infrastructure from the elements with weatherproof and flame-retardant canopies.

6. Flexible Ducting – Use in industrial air handling systems and confined space ventilation.

How Our Industrial Grade Materials Are Tested & Proven for Commercial Performance

In high-demand environments, trust starts with third-party verification. Renegade’s industrial fabrics are not only engineered for strength; they’re backed by rigorous testing to prove their safety, durability, and regulatory readiness.

- Our materials meet NFPA 701 (Test Method 1) for flame resistance, making them suitable for use in facilities where fire safety is a priority.

- For teams working across state lines, our certifications include California State Fire Marshal (Title 19) listings for both interior and exterior applications.

- All of our products are CPSIA-compliant, and entirely free from PFAS*, phthalates, lead, vinyl chloride, and cadmium.

These certifications help industrial clients meet bid requirements, streamline permitting, and reduce downstream liability.

In industries where safety standards are tightening and downtime is costly, having the right fabric partner can reduce risk and increase ROI. Our clients rely on our responsiveness, training resources, and technical documentation to keep projects running smoothly, from jobsite staging to final installation.

The Best 9 Quality Industrial Fabrics for Sale

We offer a comprehensive lineup of coated industrial fabrics tailored to specific use cases, enterprises, and performance needs:

- PPI-200 – Lightweight and flexible for general-purpose protective barriers.

- PPI-270 – A midweight option for light-duty dunnage or temporary coverings.

- PPI-370 – A heavy-duty, durable fabric ideal for containment and heavy-use tarps.

- PPI-370 Embossed – Offers enhanced grip and slip resistance for walking surfaces or curtain walls.

- PPI-420 – Our most rugged polypropylene fabric, designed for extreme applications and long-term outdoor exposure.

- Flex-270 – Lightweight and versatile, great for applications requiring flexibility and chemical resistance.

- Flex-320 Embossed – Excellent in wet or high-traffic environments where anti-slip is essential.

- Flex-370 – A balance of durability and weight for transport, industrial packaging, or ducting.

- Translucent Fabrics – Enable filtered light transmission while protecting from weather-ideal for curtains, dust covers,outdoor work zones, and shelters.

Explore technical datasheets and recommended installation options by contacting our support team or visiting our product page.

These fabrics surpass what you get with simple commodities; they’re engineered solutions. Every Renegade product is produced with repeatable quality and performance that stands up to both field demands and environmental benchmarks.

6 Critical Features that Wow Users of Our Industrial Fabrics

Why are Renegade’s materials chosen over traditional vinyl or rubber-coated options?

Because they deliver critical performance while reducing your environmental burden in several key ways:

- Lighter Weight – Easier to handle, ship, and install. Reduces ergonomic strain and freight costs.

- Chemical Resistance – Withstands corrosive materials, oils, and cleaning agents without degrading.

- Cold Temperature Flexibility – Maintains elasticity and strength even in sub-freezing conditions.

- UV Resistance – Withstands long-term sun exposure without cracking or fading.

- Waterproof – Impermeable barrier resists mold, mildew, and saturation.

- PFAS-Free*, Phthalate-Free, PVC-Free – Engineered for safer handling, better indoor air quality during fabrication and use, and compliance with modern current and emerging chemical regulations.

Whether you’re managing erosion control products or overseeing liner material installations, these benefits compound over time. Renegade fabrics not only meet spec, but outperform legacy alternatives while aligning with corporate sustainability goals and evolving compliance frameworks.

Why Renegade: A Better Way to Source Industrial Fabrics

We focus on transparency, service, and circularity. We offer:

-

- Custom fabrication support and design assistance

- Access to engineering recommendations and onsite technical assistance

- Fast-turn shipping for in-stock products from our Wisconsin distribution center

- End-of-life recycling options through our closed-loop takeback program

For applications where performance, logistics, and sustainability matter, Renegade is the partner that checks every box.

Our team of experienced professionals collaborates with engineers, procurement leaders, and installers to ensure every project runs efficiently and safely. From silt fence applications to custom ducting to geotextile fabrics, we help you choose the best products, avoid material mismatch, and stay ahead of both deadlines and regulations.

Fill out our contact form today or call (920) 348-4554 to request technical documentation, sample yardage, or a product consultation with our engineering staff.

Let’s build a cleaner, more resilient future – one roll at a time.

*(Made without intentionally adding per– and polyfluoroalkyl substances, may contain trace amounts.)